Papers: Produced with our own pulp with high quality | Klabin

We produce paper and board from its own hardwood and softwood pulp, enabling us to obtain final products and packaging with excellent performance, structure, machinability, and printability, complying with worldwide quality standards and exceeding our customers’ expectations.

Paper: an indispensable product in our daily lives | Klabin

Paper products are part of the daily life of millions of people around the world. In addition to the traditional paper for writing, it is being increasingly used in diverse types of packaging as an excellent substitute for materials from non-renewable origin, which makes it increasingly important.

What is the importance of paper?

Paper products bring convenience and agility to diverse aspects of everyday life, such as for personal hygiene. Moreover, paper is essential to produce several types of packaging that are widely used in our daily lives. Produced from an entirely renewable raw material – pulp – paper is also a great ally in building a more sustainable future. Paper is a recyclable product and an important element in the circular economy chain, since many types of paper are also biodegradable.

Origin of paper

In ancient times, before paper existed, information and ideas were recorded on more rigid materials, such as papyrus and parchment.

Books, as we know them today, with pages joined by a spine, did not exist. Written materials were organized in strips (in case of papyrus) or rolled into tubes (in case of parchment).

In mid-105 AD, Cai Lun, a Chinese citizen, changed the course of history while conducting experiments that combined cloth screens and macerated fibers. It was during these experiments that he discovered a more practical and malleable material than those in existence: paper.¹

For around 600 years, only the Chinese had access to the convenience of writing on paper. Over time, paper became popular and enabled the registration and dissemination of ideals that transformed nations, created media, communication through letters and numerous important processes.

Over time, the versatility of paper found other uses and originated products that are indispensable in our daily lives, such as transportation boxes, food packaging and bags, among others.

How is paper made?

Paper production starts in the forest. After all, it’s where we find wood, from which the most important material used in this process is extracted: pulp. Production methods may vary depending on the type of paper, but in general, they go through the following steps:

All the pulp and paper produced in Brazil comes from pine and eucalyptus forests exclusively planted for this purpose.

After harvest, tree trunks are debarked and chopped into chips, which go to a digester. Branches and barks are also used and become biomass, an important source of clean energy for the production process.

Woodchips are cooked with water and some chemical agents, resulting in the cellulose pulp.The pulp goes to the washing process where the impurities are removed.

The “mass” resulting from the pulping process goes to the paper machine, where it will become a very slim layer spread on a large felt conveyor belt, in a part of the machine called the flatbed press.

The conveyor belt takes this huge sheet through the parts of the machine that remove excess humidity and compact the material, and then to the drier. After that, the material passes special stages according to the type of paper.

At that moment, the paper is almost ready. It is wound into large rolls, which may go directly to clients or sent for cutting and packaging.

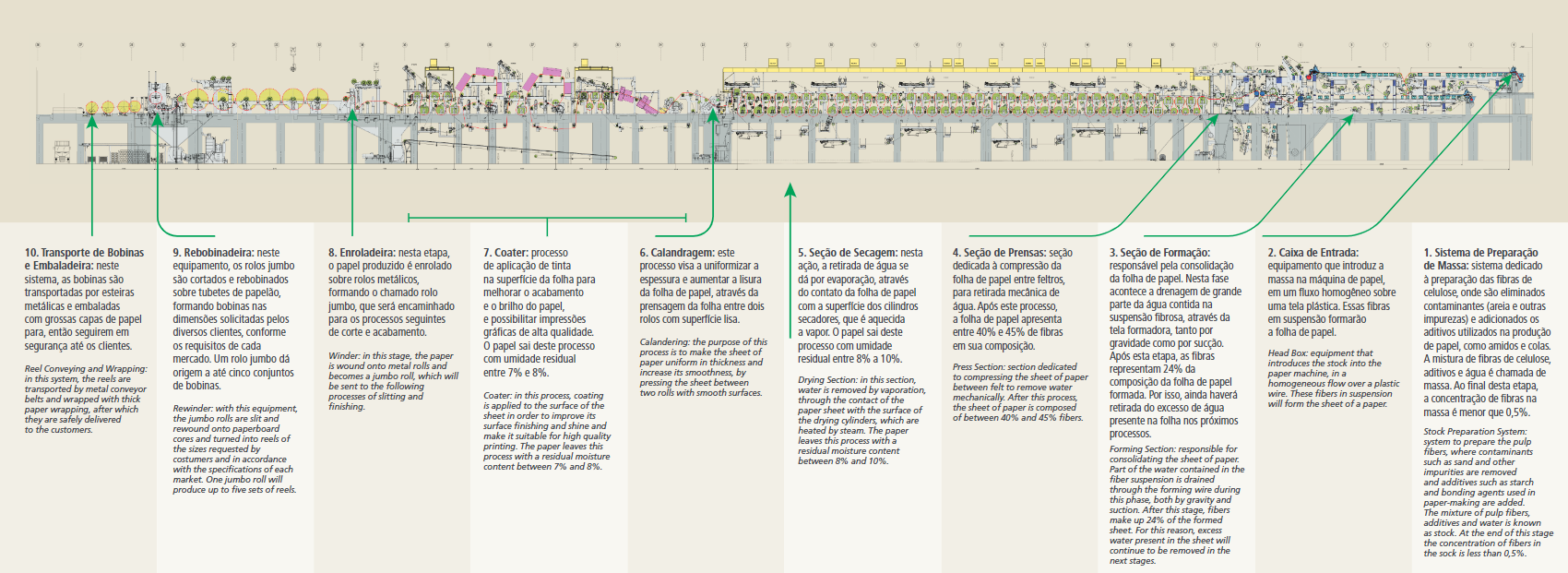

Learn about the operating steps of a paper machine:

What are the types of paper?

Paper is a highly versatile material: depending on the type of pulp used and the manufacturing process, products can range from malleable sheets to strong and resistant packaging.

In industry, retail and other sectors of the economy, the most common types of paper are kraft paper and paperboard.

Kraft paper: Kraft paper is known for being resistant and malleable at the same time. Thanks to its many possible applications, it is commonly seen in envelopes, bread bags and paper boxes. This type of paper may vary a lot in density and type of finishing, besides offering excellent print quality. Get to know Klabin's kraft paper line.

Paperboard: The main characteristic of paperboard is stiffness. This type of paper is ideal for more structured packaging, such as food boxes, since it combines good resistance and aesthetic results with great printing quality. That’s why, paperboard packaging usually highlights the final product very well. It is commonly found in long-life packaging, cereal boxes, packaging for refrigerated products and cups, to name a few. Get to know Klabin's paperboard line.

Why is paper recycling so important?

Paper also offers other advantages, such as the possibility of recycling, which gives it a new life, besides preventing the creation of new waste. This sustainable process also has great potential for direct or indirect social impact, and is an important ally of the circular economy, as well as of employment and income generation.

How is paper recycled?

First, the paper to be recycled goes through a selection process during which fragments of other materials and potentially hazardous residues are removed. The scrap is then processed in an equipment called hydro pulper and mixed with water in a process called repulping, which is very important to properly separate and reused pulp fibers.

More rigorous cleaning follows in the subsequent phases, namely washing and dispersion, which remove the remaining impurities, such as sand and other tiny contaminants. The resulting mass is then mixed with chemical agents responsible for removing paint and help form this mass, as is done in the paper mill.

After all this, the rest of the process is similar to what happens in the production of virgin paper: the mass goes through the flatbed press, the presses, drier, winder and the rewinder. The specific phases depend on the final purpose of the paper, that is, the product in which it will be used.

pt

pt

en

en

es

es

.jpg)

.jpg)